| Thermal power range: | 1.9-35Mw/hr, 1.6-30 million kcal/hr |

| Fuel Options: | Coal, Biomass pellets, Biomass briquettes, Wood chip, Corn cob, Rice husk, Palm shell, Walnut shell, Cocoa shell, Cashew shells, Coconut shell, Palm fiber, Bagasse, Urban wood waste, Bark, Production wood waste, Olive pomace, Coffee grounds, etc. |

| Design Pressure: | 1.1MPA |

| Manufacture Standard: | ASME、GB、CE-PED、ISO、EAC、DOSH、AS、MOM、NR13 |

| Key Features: |

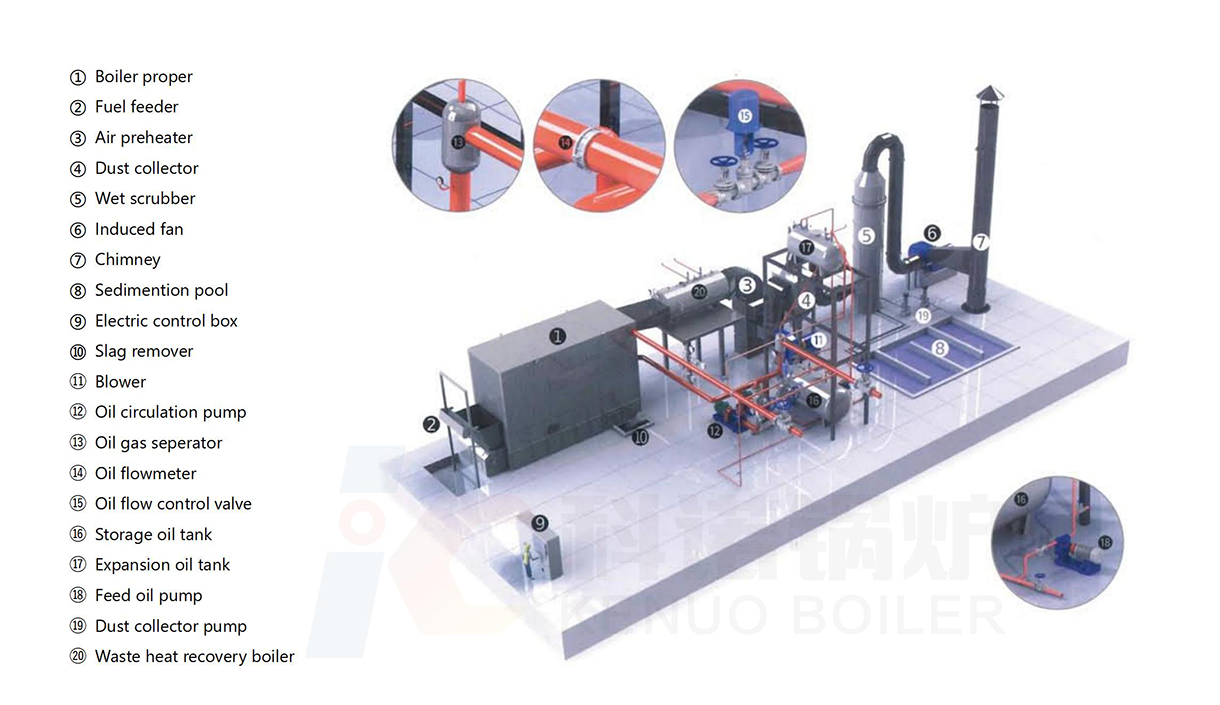

Double close coil structure, S-shaped multi-return heat exchange, high thermal efficiency. Multi-stage waste heat recovery, economizer, air preheater, waste heat boiler, low fuel consumption. Special design of grate arch, air chamber, independent adjustment of air volume, wide fuel adaptability. Reasonable heating surface layout, heats up and starts quickly, sufficient heat output. High degree of automation, easy operation, safety and reliability. Furnace heating surface adopts a special anti-wear structure, long service life. |

| Application |

Oil refinery, chemical industry, wood processing, plastic and rubber, textile printing and dyeing, papermaking, building materials, food, road asphalt heating and other industrial fields that require high temperature. |

YLW series biomass fuel fired thermal oil heater is shop-assembled forced circulation chain grate (reciprocating grate) boiler. The boiler consists of an upper boiler body and a lower grate, which will be assembled on site. The radiation heating surface of adopts a single furnace or closely square coils, rear is serpentine convection heat exchange tubes. This boiler has features of compact structure, small footprint, high assembly degree, short installation period and low installation cost. According to the characteristics of the fuel, a special anti-ash accumulation structure is adopted to reduce ash accumulation and facilitate ash cleaning. The convection heat exchange section of the boiler adopts high and low staggered arrangement, wide spacing and arrangement of soot blowing and cleaning devices to reduce boiler ash accumulation and improve boiler efficiency. Compared with traditional coal-fired boilers, it has a larger furnace combustion space to adapt to the high volatile characteristics of biomass fuel.

Steam Boiler, Hot Water Boiler, Water Tube Boiler, Thermal Oil Boiler

coal, biomass pellets, biomass briquettes, wood chips, corn cobs, rice husks, palm shells, walnut shells, cocoa shells, cashew shells, palm silk, bagasse, urban construction templates, bark, wood waste, olive pomace, coffee grounds, etc.

Performance advantages:

*Safe and reliable

1. The furnace radiation heating surface adopts densely packed coils, and the heating surface is adequately arranged, which effectively reduces the heat load on the tube surface, and the use of heat transfer oil ( thermal oil) is safer.

2. The grate adopts high temperature resistant material grate and reasonable air distribution cooling form, which is reliable and has a long service life.

3. The thermal oil flow is reasonable, from low (inlet) to high (outlet). The medium gas generated during operation is difficult to stay in the furnace and can be easily discharged from the system.

4. The feeding device adopts a locking device and distributes secondary air to effectively prevent the flame from backfired and burning the hopper.

5. The furnace radiation heat exchange surface and the convection heat exchange surface adopt special anti-wear structure according to the special biomass fuel combustion characteristics.

6. The boiler heating surface pipe docking fully automatic gas shielded welding process and equipment can be 100% real-time X-ray online Detection. The welding quality is stable and reliable.

7. The boiler operation adopts remote and near-ground monitoring, and the automatic control and monitoring instruments are complete, safe and reliable, and easy operation. Combining industrial automation control technology, Internet technology, computer software and artificial intelligence technology to establish an industrial boiler Internet of Things platform, remote human-computer interaction and data sharing can be realized, and automatic control can be realized.

*High efficiency and energy saving

1. The furnace radiation heat exchange section adopts a double-closed coil structure, and the convection heat exchange section adopts an S-shaped multi-return heat exchange.

2. The tail is equipped with an air preheater, a steam waste heat boiler, and a hot water economizer according to the user's waste heat usage to recover waste heat, reduce exhaust temperature, improve boiler efficiency, reduce fuel consumption, and save energy.

3. The boiler adopts high-quality insulation materials and special construction technology, with less heat dissipation loss, low exhaust temperature, and high boiler thermal efficiency.

4.The grate combustion chamber designed higher, and the secondary air for combustion is arranged, so that the fuel burns evenly and fully, and the combustion efficiency is high.

5. The grate arch is specially designed, the grate is divided into compartments for air intake, the air volume is independently adjusted, and the fuel adaptability is wide.

6. The tail convection heat exchange section adopts a special structure and is equipped with a soot blowing device, which does not accumulate soot during operation and has high heat exchange efficiency.

7. The heating surface is arranged reasonably, the boiler heats up and starts quickly, and sufficient heat output.

*Environmental protection:

According to the local atmospheric pollutant emission standards, a flue gas treatment device is configured.

|

Model |

Rated thermal power(Kw/h) |

Design pressure(MPA) |

Max oil work temperature(℃) |

Heat Efficiency(%) |

Applicable Fuel |

Main pipe size(DN) |

Total installed power(Kw) |

|---|---|---|---|---|---|---|---|

|

YLW1900-SCII |

1900 |

1.1 |

320 |

≥82 |

Coal, biomass |

150 |

82 |

|

YLW2300-SCII |

2300 |

1.1 |

320 |

≥82 |

Coal, biomass |

150 |

82 |

|

YLW2900-SCII |

2900 |

1.1 |

320 |

≥82 |

Coal, biomass |

200 |

105 |

|

YLW3500-SCII |

3500 |

1.1 |

320 |

≥82 |

Coal, biomass |

200 |

105 |

|

YLW4100-SCII |

4100 |

1.1 |

320 |

≥82 |

Coal, biomass |

200 |

107 |

|

YLW4700-SCII |

4700 |

1.1 |

320 |

≥83 |

Coal, biomass |

200 |

148 |

|

YLW7000-SCII |

7000 |

1.1 |

320 |

≥83 |

Coal, biomass |

250 |

202 |

|

YLW8200-SCII |

8200 |

1.1 |

320 |

≥87 |

Coal, biomass |

250 |

222 |

|

YLW9400-SCII |

9400 |

1.1 |

320 |

≥87 |

Coal, biomass |

300 |

280 |

|

YLW10500-SCII |

10500 |

1.1 |

320 |

≥87 |

Coal, biomass |

300 |

325 |

|

YLW12000-SCII |

12000 |

1.1 |

320 |

≥87 |

Coal, biomass |

2-250/350 |

347 |

|

YLW14000-SCII |

14000 |

1.1 |

320 |

≥87 |

Coal, biomass |

2-300/400 |

387 |

|

YLW16300-SCII |

16300 |

1.1 |

320 |

≥87 |

Coal, biomass |

2-300/400 |

500 |

|

YLW19000-SCII |

19000 |

1.1 |

320 |

≥87 |

Coal, biomass |

2-300/400 |

617 |

|

YLW21000-SCII |

21000 |

1.1 |

320 |

≥87 |

Coal, biomass |

2-300/400 |

672 |

|

YLW23500-SCII |

23500 |

1.1 |

320 |

≥87 |

Coal, biomass |

4-200/400 |

683 |

|

YLW29000-SCII |

29000 |

1.1 |

320 |

≥87 |

Coal, biomass |

4-300/500 |

793 |