| Steam Capacity Range: | 1-25 ton/hour |

| Fuel Options: | Biomass pellets, Biomass briquettes, Wood chip, Bamboo chip, Palm shell, Walnut shell |

| Steam Pressure: | 1.0MPA-2.5MPA |

| Manufacture Standard: | ASME、GB、CE-PED、ISO、EAC、DOSH、AS、MOM、NR13 |

| Key Features: |

Semi-gasification combustion, combustion efficiency up to 94%; Flame output temperature can reach 1200℃,sufficient heat output, boiler thermal efficiency ≥92%; Applicable multi biomass fuels and can be alternately work with oil or gas burners; Only two parts biomass burner and boiler body, easy to install and occupies small area; High degree automation control, reliable and stable operation. |

| Application: |

Food processing, beverage, textile, paper-making, pharmaceutical, chemical, building material, hospital, hotel, laundry, etc. |

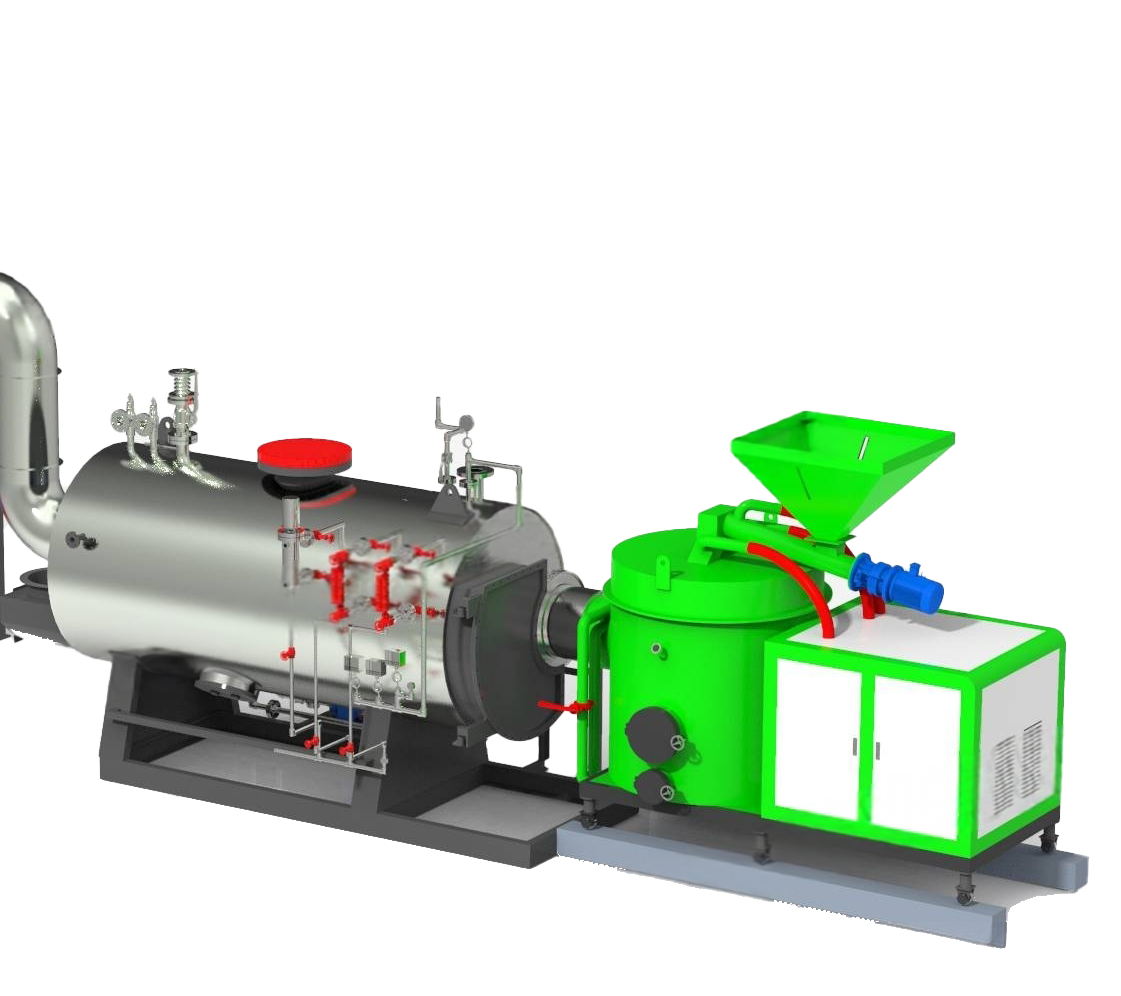

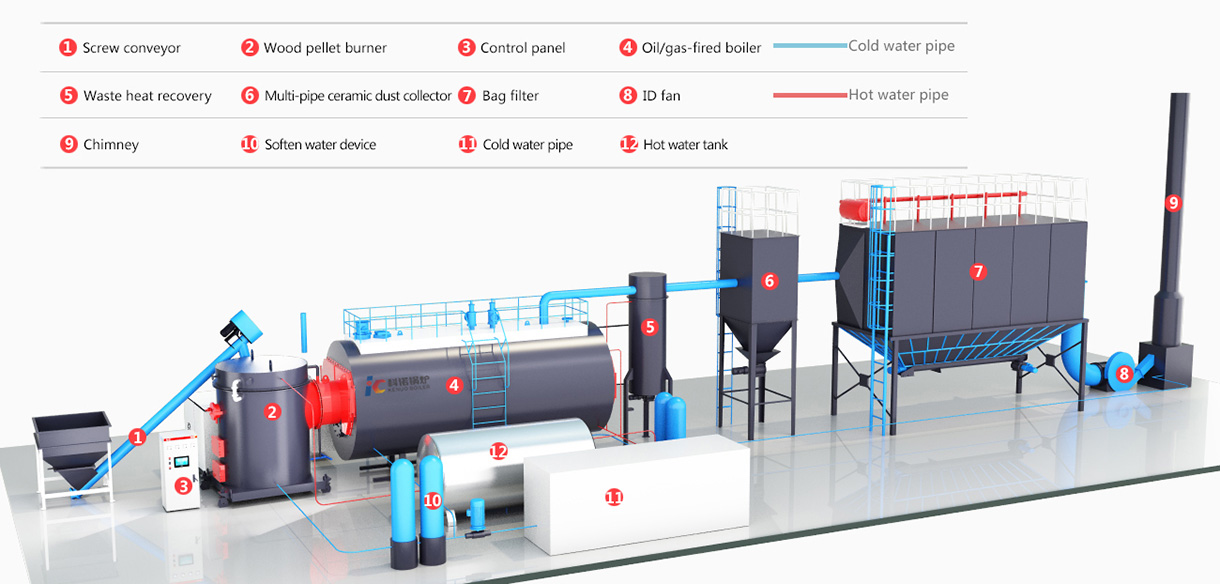

The WWS-T series biomass steam boiler adopts low-temperature semi-gasification combustion technology, with a combustion efficiency of up to 94%. The boiler is composed of a biomass burner and a fire tube boiler body or a water tube boiler body. The combustion process is biomass fuel enters the furnace of the semi-gasification burner, passes through the gasification zone, combustion zone, and burnout zone, and finally burns into ash and slag and is discharged. WWS-T series biomass boiler shipment will have two main big parts, biomass burner and boiler body. On-site installation is as fast as oil and gas boilers, short installation period and low operating costs, saving money for users.

1. Adopt low-temperature semi-gasification combustion technology, combustion efficiency up to 94%;

2. The flame output temperature of the biomass burner can reach 1200℃, with sufficient heat output and boiler thermal efficiency ≥92%;

3. Applicable multi biomass fuels and can be used alternately with oil and gas burners;

4. The boiler consists of two major parts: biomass burner and boiler body, easy to install and occupies small area;

5.Fast start-up, rapid temperature rise, simple operation, and can be used alternately with oil burners and gas burners.

6. High degree automation control, reliable and stable operation.

Steam Boiler, Hot Water Boiler, Water Tube Boiler, Thermal Oil Boiler

|

Model |

Rated steam output(TPH) |

Rated working pressure(MPA) |

Rated Steam Temperature(℃) |

Heat Efficiency(%) |

Applicable Fuel |

Transportation Weight(ton) |

Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

WNS1 |

1 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

8 |

4300×1860×2100 |

|

WNS2 |

2 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

8 |

5500×2250×2430 |

|

WNS3 |

3 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

10 |

5900×2350×2500 |

|

WNS4 |

4 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

12 |

6500×2510×2700 |

|

WNS6 |

6 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

15.5 |

7200×2750×2800 |

|

WNS8 |

8 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

18 |

7700×2950×3000 |

|

WNS10 |

10 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

22 |

8100×2950×3350 |

|

SZS15 |

15 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

40 |

9000×3900×3950 |

|

SZS20 |

20 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

51 |

9500×3900×4050 |

|

SZS25 |

25 |

1.0/1.25/1.6/2.5 |

184/194/204/226 |

≥88 |

Biomass |

40 |

13000×3800×4200 |