Industrial steam boilers play a crucial role in the paper manufacturing industry. From pulp production to paper drying, the steam generated by the industrial boilers ensures continuous production. With the assistance of the high-efficiency steam boiler, the paper manufacturing process can be more stable and efficient. Let’s explore how boilers operate in the paper industry and why choosing the right industrial boiler system matters.

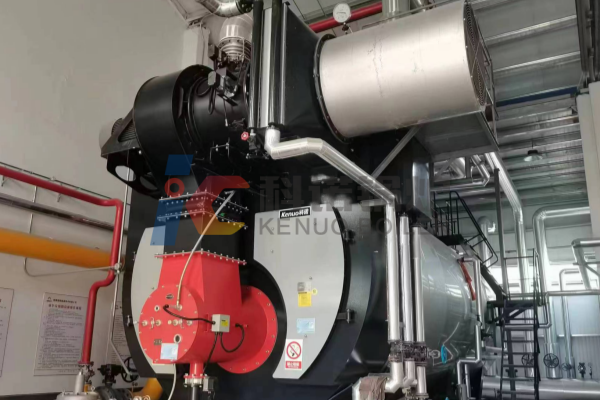

In paper mills, high-temperature steam is responsible for some fundamental processes, when it comes to the pulp and paper processes. With several successful experiences in providing stable steam supply, Kenuo knows how to optimize the industrial boiler system in paper mills.

In order to produce paper, paper pulp cooking is one of the most important steps. Industrial steam boilers are capable of providing sufficient steam continuously, which can guarantee stable pulp cooking. High-temperature steam can soften raw materials such as wood chips and plant fiber defibrination. Full preparation can improve the quality of the pulp and the paper products.

During the process of paper manufacturing, the industrial steam boiler shoulders multiple tasks to achieve high efficiency and high-quality production. The owners of paper mills have high standards for the industrial boilers as well.

During the process of paper manufacturing, the industrial steam boiler shoulders multiple tasks to achieve high efficiency and high-quality production. The owners of paper mills have high standards for the industrial boilers as well.

Fuel and other costs of the boiler are important parts of maintaining the daily operation of the industrial boiler. The higher efficiency the boiler machine gets, the lower the costs the boiler maintains. With the development of modern technology, more and more business owners have higher standards for industrial steam boiler machines.

For an industry like paper manufacturing, the supply of high-temperature steam is essential. The industrial steam boiler can produce the stable steam that paper mills require. The stable steam supply can support continuous operation.

With the enhancement of the awareness of environmental protection, industrial production starts to have higher standards for machine operating. During steam production, the burning of the fuel would cause emissions. Kenuo Boiler adopts the most advanced technology and equipment to lower emissions. With the assistance of reliable manufacturers, the emission standards can meet the increasingly strict regulations.

The growing modern technology raises the customer’s requirements. As for the paper-making industry, the importance of the industrial steam boiler is something that the manufacturers cannot ignore. During the 30 years of development, Kenuo has been dedicated to providing products with high-quality and highest-level technology. Our company can provide the most suitable solution for the customers based on our more than 30 years of experience.

In the paper-making industry, choosing an efficient and environmentally friendly boiler system can not only improve production efficiency but also control operational costs, aligning with the trend of green production. Kenuo is committed to becoming a reliable partner of your business and supporting the sustainable development of our customer business. Learn more about the specialized industrial steam boilers for paper mills. Bring more power to your production line!