| Steam Capacity Range: | 6-60 t/h |

| Fuel Options: | Coal, Washed peas coal, Biomass pellets, Biomass briquettes, Wood chip, Corn cob, Rice husk, Palm shell, Walnut shell, Cocoa shell, Cashew shells, Coconut shell, Palm fiber, Bagasse, Urban wood waste, Bark, Production wood waste, Olive pomace, Coffee grounds, etc. |

| Steam Pressure: | 1.0MPA-3.82MPA |

| Manufacture Standard: | ASME、GB、CE-PED、ISO、EAC、DOSH、AS、MOM、NR13 |

| Key Features: |

S-shape flue gas multi-return design, high thermal efficiency; High-efficiency H-shaped fin economizer and a tube-in-tube air preheater, thermal efficiency up to 88%; Tall and large combustion chamber, high combustion efficiency, and prevents carbon deposition; Unique fuel feeding design and anti-backfire technology solve the problems of pre-combustion Shop-assembled boiler, short installation time. Adapt to travelling chain grate, reciprocating grate etc. |

| Application: |

Food processing, beverage, Palm oil mill, Sugar, textile, paper-making, pharmaceutical, chemical, building material, hospital, hotel, laundry, etc. |

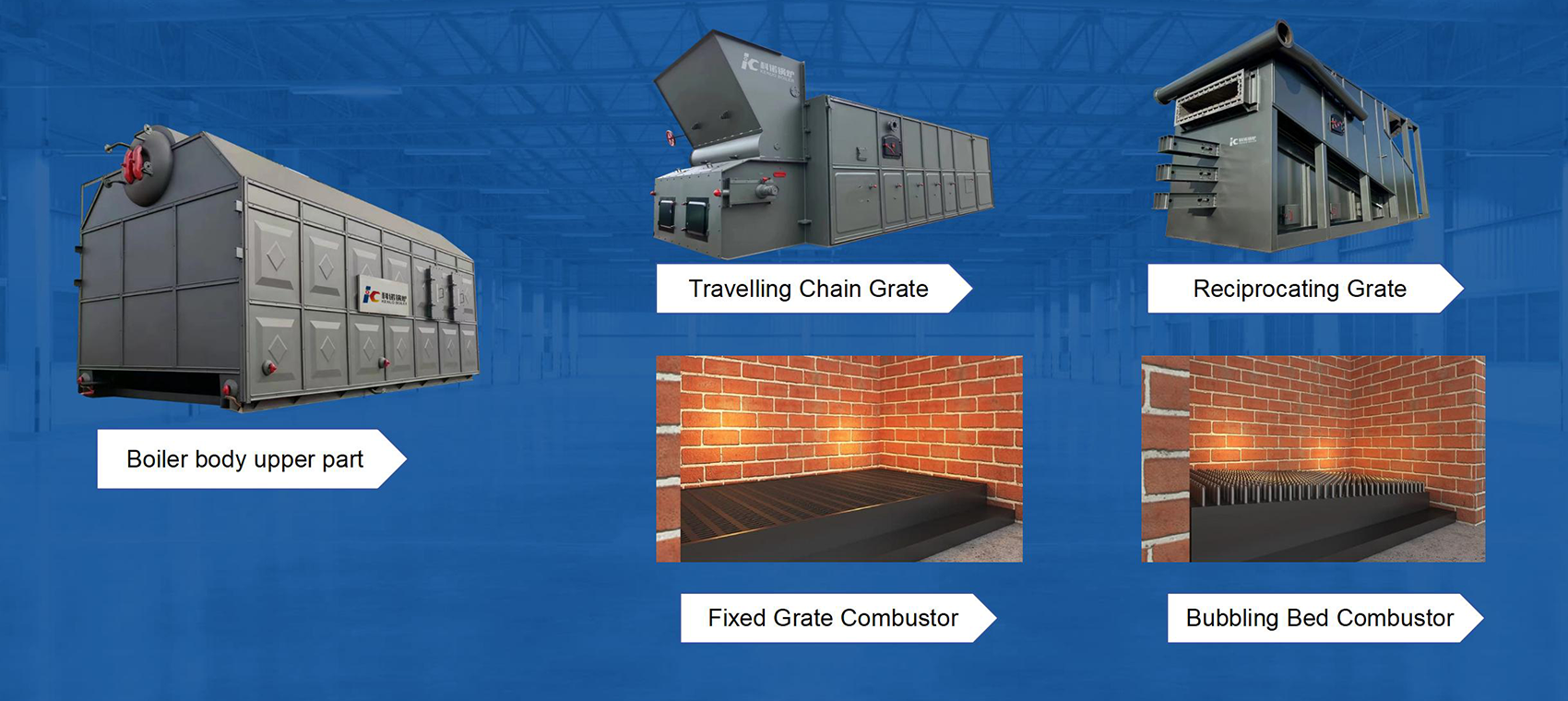

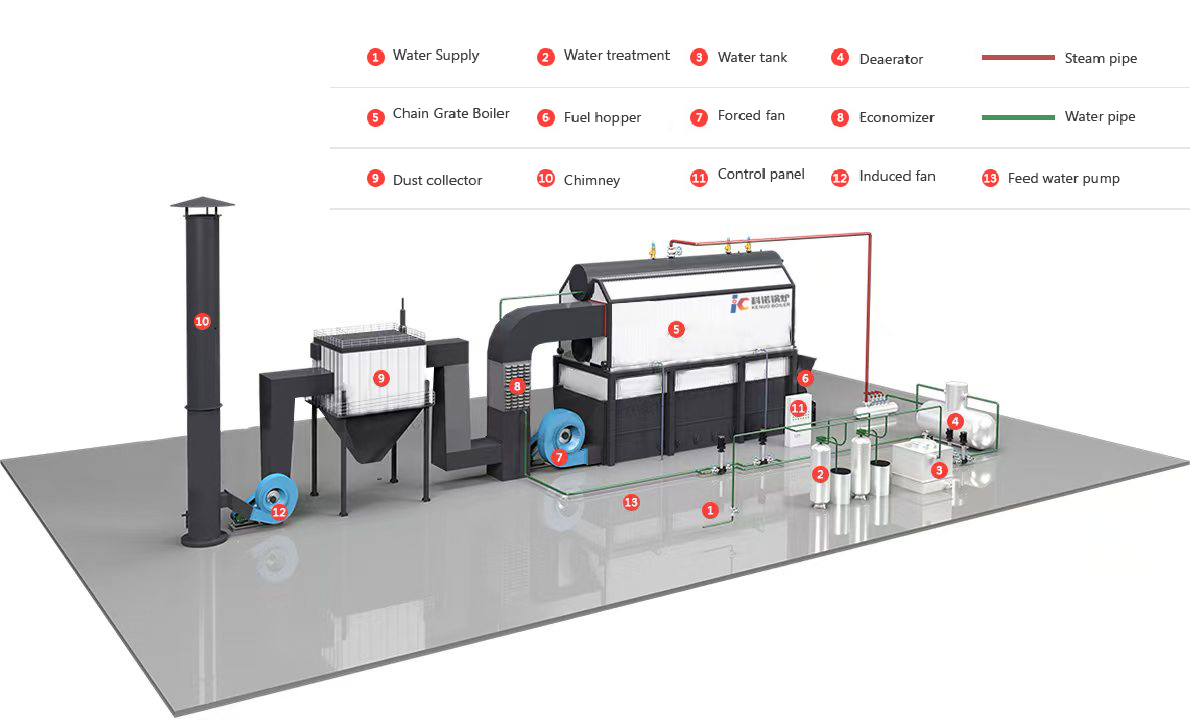

The SZ series shop-assembled steam boiler, adopts a double-drum water tube structure. The boiler body consists of upper drum, lower drum, water-cooled wall tube, convection tube bundle, downcomer, header, etc. The water-cooled wall tubes constitute the radiation heating surface of the furnace, the tube bundle between the upper drum and the lower drum constitutes the convection heating surface, and the economizer and air preheater are arranged at the tail.

Kenuo Boiler can customize design the combustion devices according to the fuel calorific value, size, moisture, ash content, and ash melting point, Select the suitable combustion type, fixed grate, chain grate, reciprocating grate, bubbling bed, circulating fluidized bed (CFB). Make the boiler applicable for coal as well as various biomass fuels such as Biomass pellets, Biomass briquettes, Wood chip, Corn cob, Rice husk, Palm shell, Walnut shell, Cocoa shell, Cashew shells, Coconut shell, Palm fiber, Bagasse, Urban wood waste, Bark, Production wood waste, Olive pomace, Coffee grounds, etc.

Steam Boiler, Hot Water Boiler, Water Tube Boiler, Thermal Oil Boiler

|

Model |

Rated steam output(TPH) |

Rated working pressure(MPA) |

Rated Steam Temperature(℃) |

Heat Efficiency(%) |

Applicable Fuel |

Transportation Weight(ton) |

Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

SZL(W)6 |

6 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

20(25) |

6500×2700×3500 |

|

SZL(W)8 |

8 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

22(28) |

7100×3400×3600 |

|

SZL(W)10 |

10 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

25(33) |

7900×3400×3600 |

|

SZL(W)12 |

12 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

26 |

8900×3400×3600 |

|

SZL(W)15 |

15 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

28 |

9600×3400×3600 |

|

SZL(W)20 |

20 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

30 |

10600×3500×3600 |

|

SZL(W)25 |

25 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

35.6 |

11700×3800×3700 |

|

SZL(W)30 |

30 |

1.25/1.6/2.5 |

194/204/226 |

≥84 |

Coal, biomass |

32 |

10000×3700×3800 |