Selecting the right industrial boiler capacity is crucial for ensuring optimal performance, energy efficiency, and safety in industrial operations. Boilers are the backbone of many manufacturing and processing facilities, providing the necessary heat or steam for production, heating, and other industrial applications. Choosing an incorrect capacity can lead to wasted energy, frequent maintenance issues, or even operational downtime. This guide will help you understand the key considerations in selecting the appropriate boiler capacity for your facility.

The capacity of an industrial boiler refers to its ability to produce steam or hot water over a given period, typically measured in kilograms per hour (kg/h), tons per hour (t/h), or megawatts (MW) for heat output. Selecting a boiler with the correct capacity ensures that your factory has a steady and reliable supply of energy without overloading or underutilizing the system.

When calculating capacity, consider your plant’s maximum and average energy demands. Overestimating capacity may increase upfront costs and energy consumption, while understanding it could compromise production efficiency.

In order to choose the right capacity of the industrial boiler machine, the business owner should have a clear view of the production facility. The customer can also provide the productivity of the factory for our professional engineering team to offer the customized solution based on the working conditions.

The fuel type significantly impacts boiler efficiency and operating costs. Common fuels include natural gas, diesel, biomass, coal, and electricity. Each fuel type has different calorific values, which affect the required boiler capacity. For example, biomass boilers often require slightly larger capacities due to lower energy density compared to fossil fuels.

Evaluate your factory’s steam or hot water requirements for all operational processes. For example, in food processing or chemical manufacturing, steam demand can vary throughout the day. Choosing a boiler capacity that aligns with peak and average demands ensures stable operation.

Higher efficiency boilers can reduce fuel consumption to assist the business owner save costs. Modern high-efficiency industrial boilers utilize advanced heat exchange technologies, economizers, and intelligent control systems to minimize waste. Investing in an efficient boiler ensures long-term cost savings and environmental compliance.

Consider potential growth when selecting boiler capacity. A facility planning to expand production in the future may require a boiler with higher capacity or a modular system that can be upgraded. This foresight prevents the need for costly replacements or additional boilers later.

TIndustrial boiler systems can be larger and require proper installation space. Evaluate your facility layout, clearance requirements, and accessibility for maintenance. Some high-capacity boilers require specialized foundations or additional equipment like blowdown tanks, feedwater pumps, or economizers.

• Optimized Fuel Consumption

Correct sizing prevents overfiring, reducing fuel waste and operational costs.

• Improved Operational Efficiency

Ensures consistent steam or hot water supply for industrial processes by adopting advanced technologies.

• Extended Equipment Lifespan

Reduces wear and tear from underutilized or overworked boilers.

• Safety Compliance

Proper capacity selection minimizes the risk of overheating or pressure issues.

Choosing the right industrial boiler capacity is a balance between current production needs, energy efficiency, and future expansion plan. By analyzing the factory’s requirements, fuel type, operational patterns, and space limitations, the business owner can select a boiler that provides reliable, efficient, and safe energy for the industrial operations.

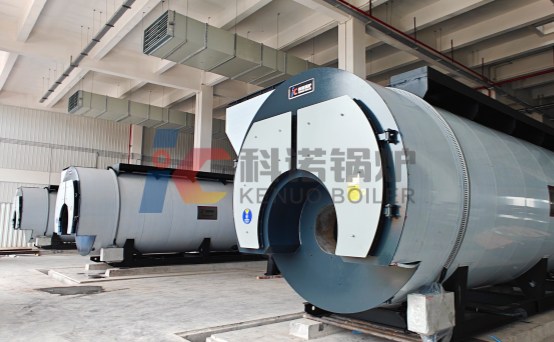

With more than 30 years of experience of industrial boiler manufacturing, Kenuo Boiler can provide the most suitable solutions for the customers. Kenuo is dedicated to improve the performance of the boiler machine by adopting durable materials and advanced technologies. Are you looking for a trustworthy industrial boiler manufacturer? Do not hesitate to contact us for your customized plan and learn more about our high-quality products.