| Steam Capacity Range: | 2-30 ton/hour, 100-2100BHP |

| Fuel Options: | Natural Gas, LPG, LNG, Diesel, Heavy Oil, Dual Fuel , Propane |

| Steam Pressure: | 1.0MPA-2.5MPA |

| Manufacture Standard: | ASME、GB、CE-PED、ISO、EAC、DOSH、AS、MOM、NR13 |

| Key Features: |

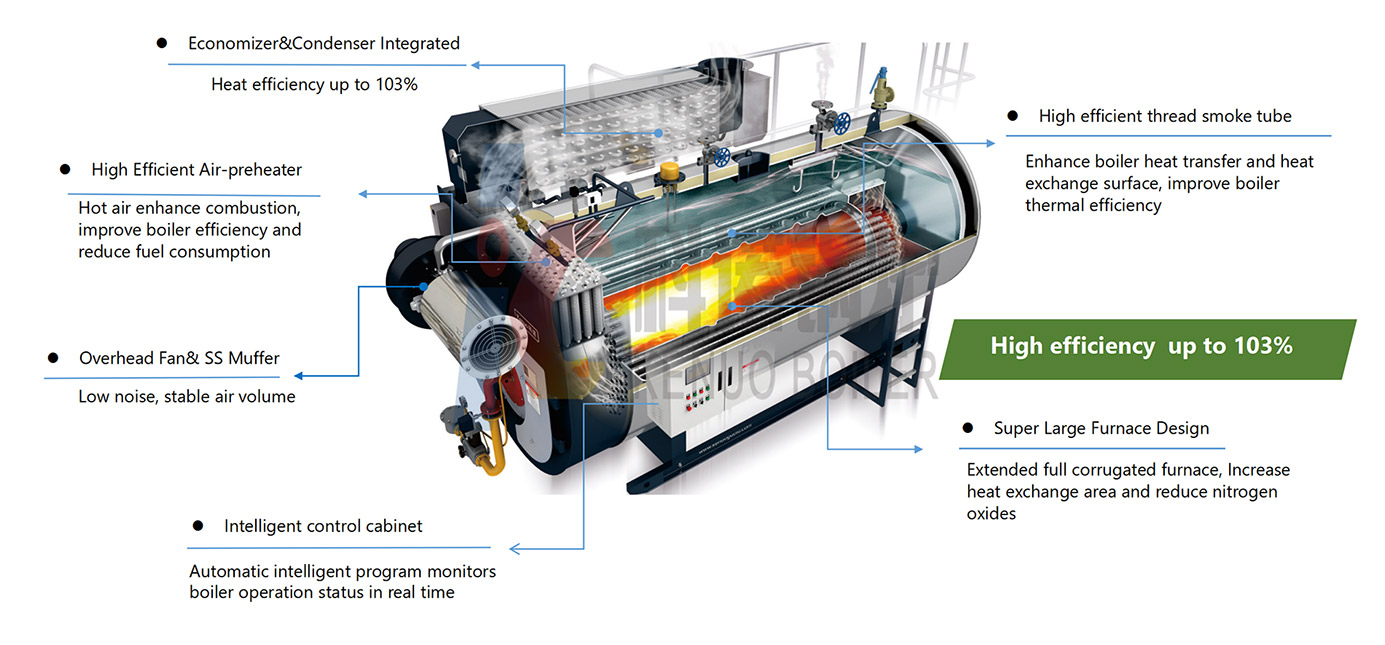

Highly Integration, minimize boiler footprint & simplest installation. Combustion & water feeding VFD control, save electricity 30%. Burnout rate 99.99%, low NOx emission and lowest operation cost. Lifetime maintenance-free smoke box without refractory cement. Oval track shape reversal chamber, steam dryness 99%. |

| Application |

Food processing, beverage, textile, paper-making, pharmaceutical, chemical, building material, hospital, hotel, laundry etc. |

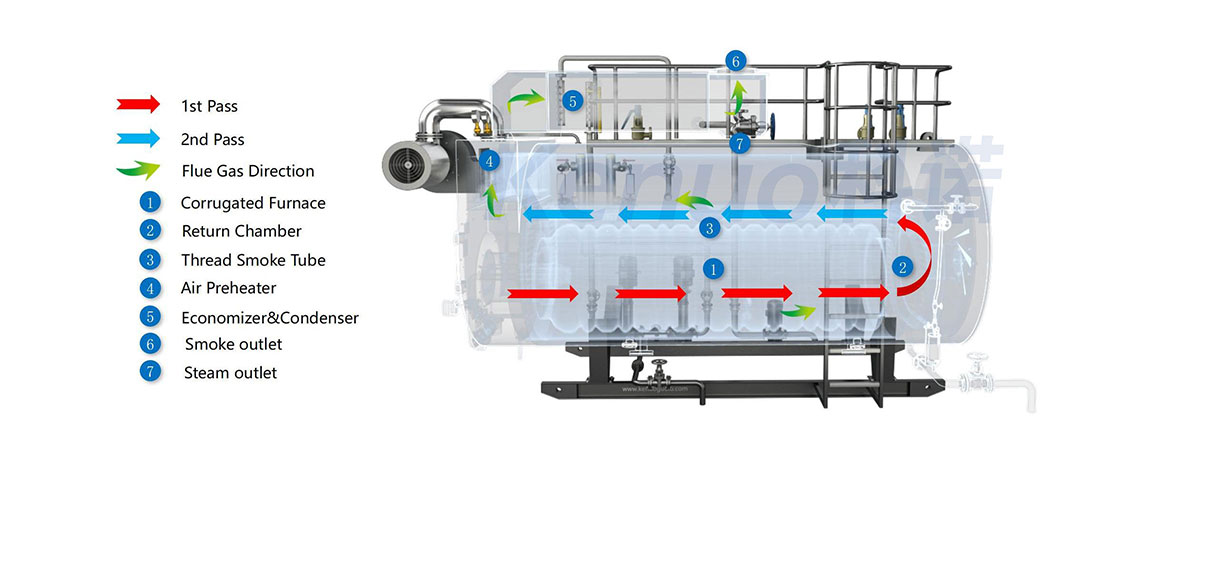

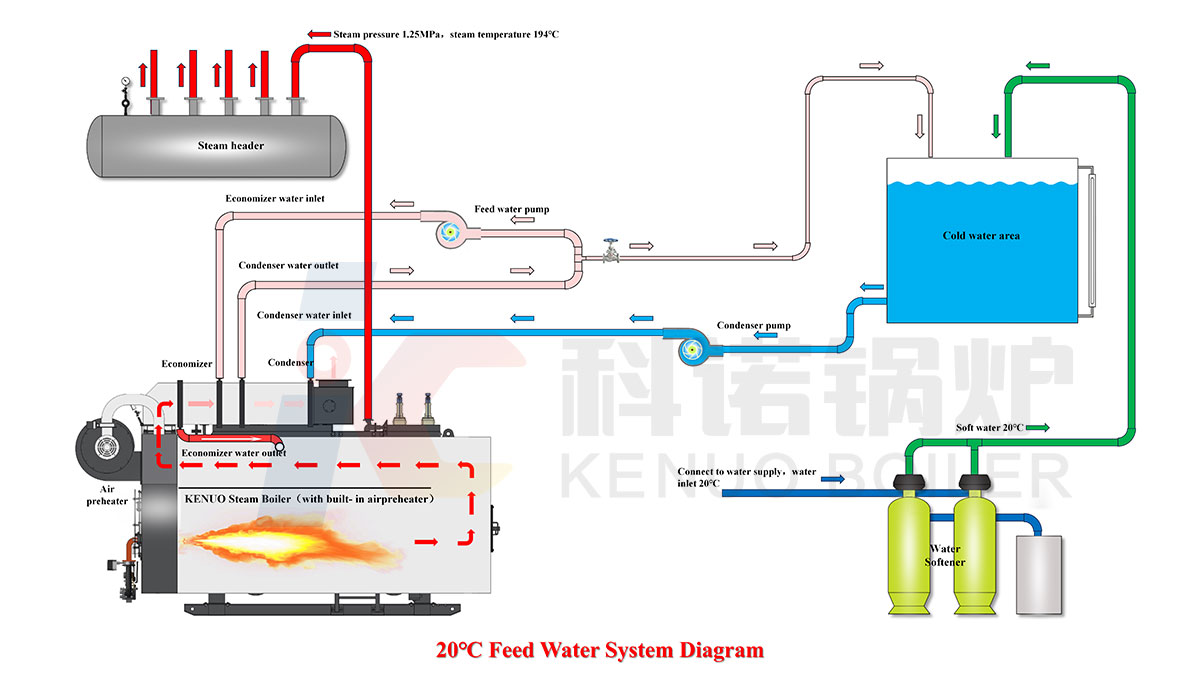

Kenuo LNZ-Q series gas oil condensing steam boiler, boiler body adopts two-pass wetback structure, a front-mounted integrated high-efficiency fresh air preheater (3-pass) and an external low-resistance ring-wing-shaped integrated economizer & condenser (5-pass) design. An arc-shaped double-open furnace door for easy maintenance, air-cooled smoke box , and uses a large furnace for full-mixed combustion and high-efficiency threaded smoke tube heat transfer; it is the first to use low-nitrogen coupling and has a unique low-nitrogen combustion technology in the furnace to comprehensively suppress the production of nitrogen oxides (NOx); Equipped with ABB inverters, split low-nitrogen burners, 7/10-inch LCD touch screens and high-performance PLC programmable controllers, which fully meet the boiler's ultra-low NOx emission standards.

Hot Water Boiler, Water Tube Boiler, Biomass Boiler, Thermal Oil Boiler

|

Model |

Rated steam output(TPH) |

Rated working pressure(MPA) |

Rated Steam Temperature(℃) |

Heat Efficiency(%) |

Nox Emission(mg/m³) |

Transportation Weight(ton) |

Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

WNS2-1.25-Y(Q) |

2 |

1.25 |

194 |

≥96 |

≤80/30 |

8.2 |

4960*2140*2340 |

|

WNS3-1.25-Y(Q) |

3 |

1.25 |

194 |

≥96 |

≤80/30 |

9.8 |

5280*2240*2380 |

|

WNS4-1.25-Y(Q) |

4 |

1.25 |

194 |

≥96 |

≤80/30 |

12.9 |

5720*2440*2570 |

|

WNS5-1.25-Y(Q) |

5 |

1.25 |

194 |

≥96 |

≤80/30 |

16.6 |

6200*2700*3900 |

|

WNS6-1.25-Y(Q) |

6 |

1.25 |

194 |

≥96 |

≤80/30 |

17.2 |

6690*2630*2660 |

|

WNS8-1.25-Y(Q) |

8 |

1.25 |

194 |

≥96 |

≤80/30 |

21.5 |

6800*2800*3050 |

|

WNS10-1.25-Y(Q) |

10 |

1.25 |

194 |

≥96 |

≤80/30 |

27.5 |

7250*2900*3250 |

|

WNS12-1.25-Y(Q) |

12 |

1.25 |

194 |

≥96 |

≤80/30 |

30.3 |

7750*3100*3500 |

|

WNS15-1.25-Y(Q) |

15 |

1.25 |

194 |

≥96 |

≤80/30 |

37.5 |

8000*3300*3700 |

|

WNS20-1.25-Y(Q) |

20 |

1.25 |

194 |

≥96 |

≤80/30 |

49.3 |

9050*3500*4050 |

|

WNS25-1.25-Y(Q) |

25 |

1.25 |

194 |

≥96 |

≤80/30 |

57.6 |

9850*3700*4300 |