| Steam Capacity Range: | 2-30 ton/hour, 100-2100BHP |

| Fuel Options: | Natural Gas, LPG, Diesel, Heavy Oil, Dual Fuel , Propane |

| Steam Pressure: | 1.0MPA-2.5MPA |

| Manufacture Standard: | ASME、GB、CE-PED、ISO、EAC、DOSH、AS、MOM、NR13 |

| Key Features: |

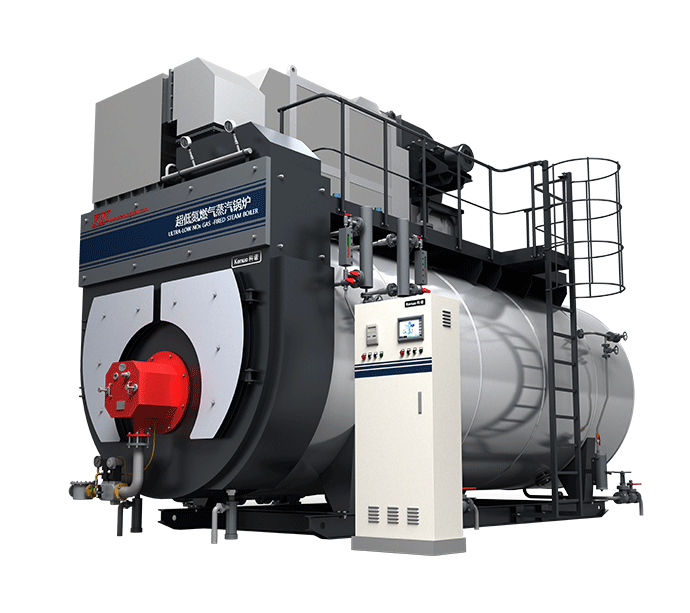

Integrated economizer, condenser, air preheater, minimize footprint. VFD control for water feeding & combustion, save electricity 30%. Boiler efficiency up to 103%, lowest fuel cost. No refractory smoke box, lifetime maintenance free. Oval track shape reversal chamber, steam dryness 99%. Craftsmanship quality, burner lifetime warranty. |

| Application |

Food processing, beverage, textile, paper-making, pharmaceutical, chemical, building material, hospital, hotel, laundry etc. |

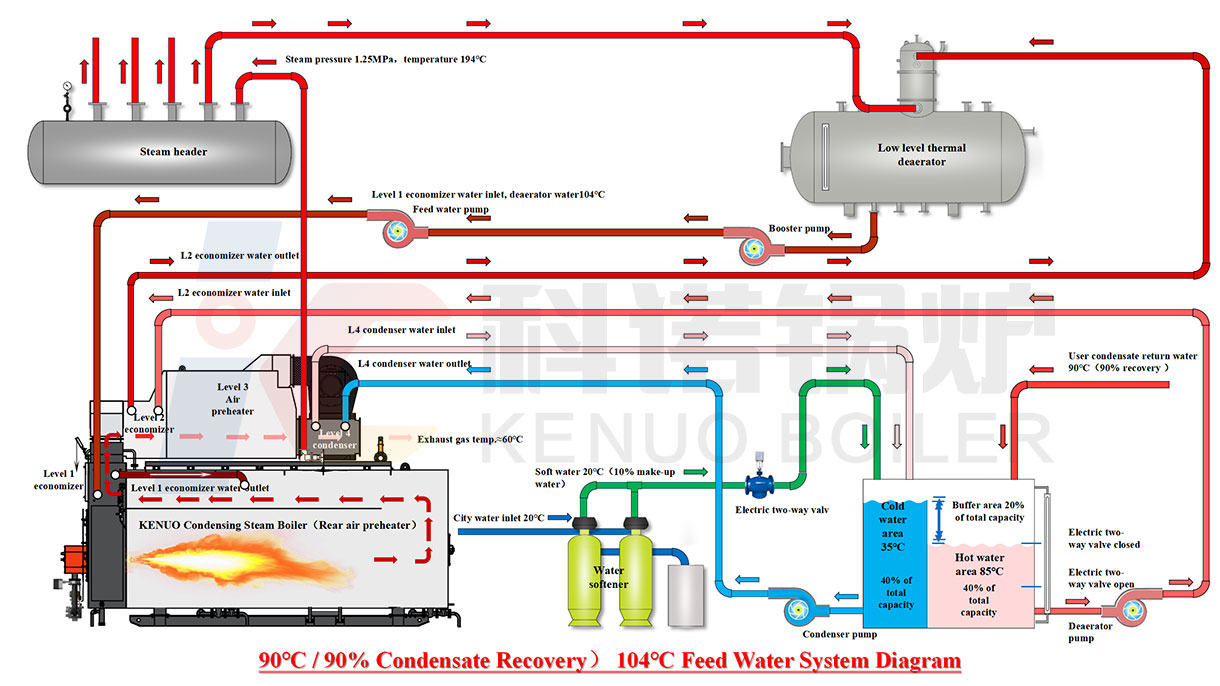

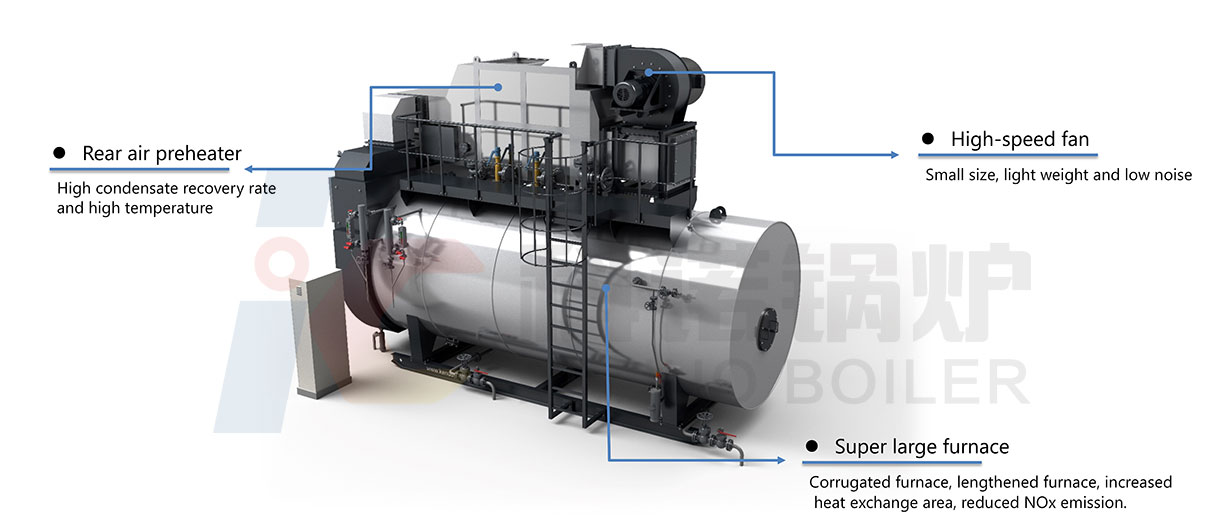

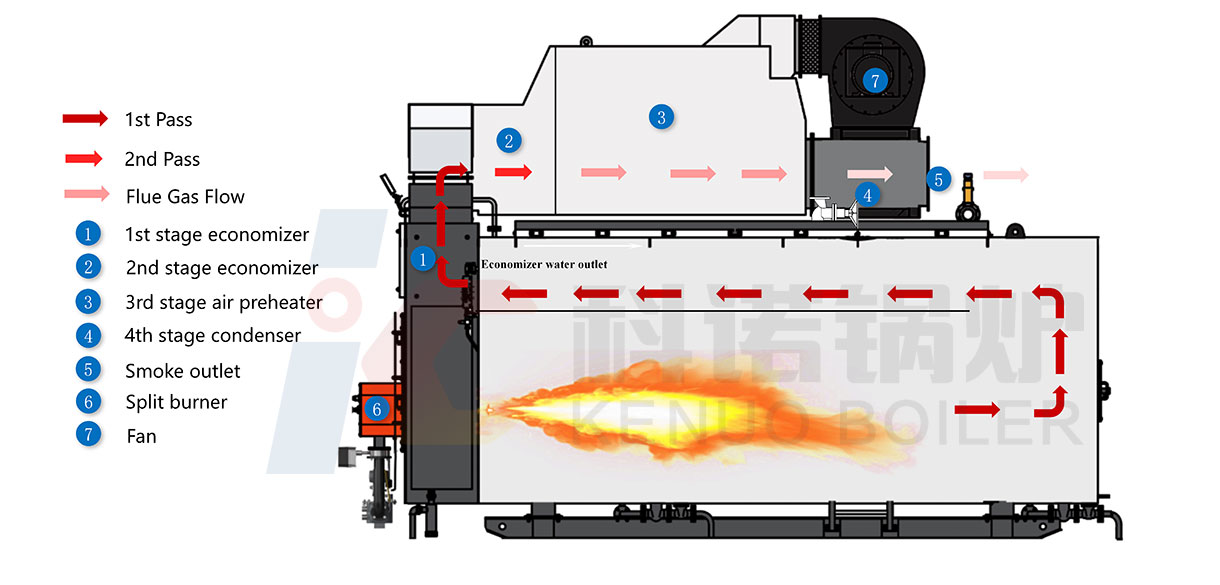

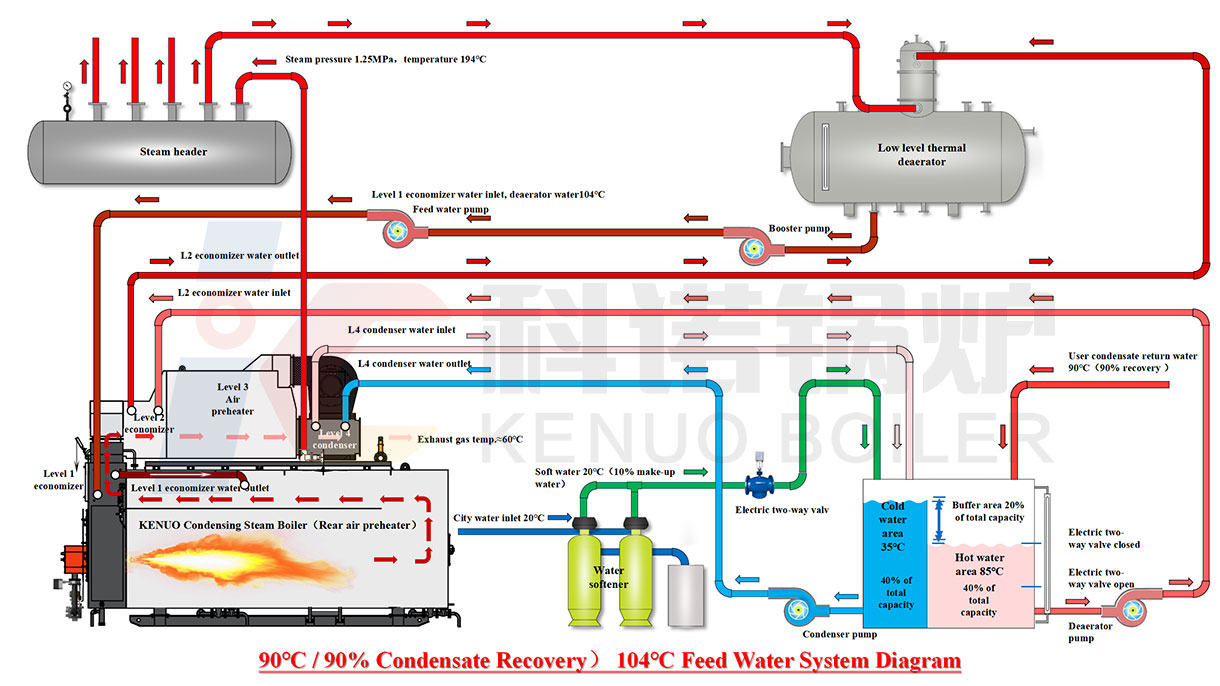

For the steam system with high condensate recovery rate and high condensate return temperature, and users who have higher system energy saving requirements, Kenuo engineers design the Rear Air Preheating condensing steam boiler. the high efficiency air pre-heater plus the integrated economizer and condenser, further reduce the smoke exhaust temperature lowest to 60 degree C., it can greatly save energy and improve boiler thermal efficiency. This boiler adopts the Surpass traditional two pass (high efficiency and low stress) fully wet back boiler body structure, arc-shaped double-open furnace door for easy maintenance. Equipped with high-efficiency air preheater, low-resistance airfoil economizer and condenser, the sensible heat and latent heat of vaporization in flue gas are recovered to the maximum extent. Boiler thermal efficiency can be up to 103%.

Hot Water Boiler, Water Tube Boiler, Biomass Boiler, Thermal Oil Boiler

|

Model |

Rated steam output(TPH) |

Rated working pressure(MPA) |

Rated Steam Temperature(℃) |

Heat Efficiency(%) |

Nox Emission(mg/m³) |

Transportation Weight(ton) |

Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

WNS2-1.25-Y(Q) |

2 |

1.25 |

194 |

≥96 |

≤80/30 |

8.2 |

4960*2140*2340 |

|

WNS3-1.25-Y(Q) |

3 |

1.25 |

194 |

≥96 |

≤80/30 |

9.8 |

5280*2240*2380 |

|

WNS4-1.25-Y(Q) |

4 |

1.25 |

194 |

≥96 |

≤80/30 |

12.9 |

5720*2440*2570 |

|

WNS5-1.25-Y(Q) |

5 |

1.25 |

194 |

≥96 |

≤80/30 |

16.6 |

6200*2700*3900 |

|

WNS6-1.25-Y(Q) |

6 |

1.25 |

194 |

≥96 |

≤80/30 |

17.2 |

6690*2630*2660 |

|

WNS8-1.25-Y(Q) |

8 |

1.25 |

194 |

≥96 |

≤80/30 |

21.5 |

6800*2800*3050 |

|

WNS10-1.25-Y(Q) |

10 |

1.25 |

194 |

≥96 |

≤80/30 |

27.5 |

7250*2900*3250 |

|

WNS12-1.25-Y(Q) |

12 |

1.25 |

194 |

≥96 |

≤80/30 |

30.3 |

7750*3100*3500 |

|

WNS15-1.25-Y(Q) |

15 |

1.25 |

194 |

≥96 |

≤80/30 |

37.5 |

8000*3300*3700 |

|

WNS20-1.25-Y(Q) |

20 |

1.25 |

194 |

≥96 |

≤80/30 |

49.3 |

9050*3500*4050 |

|

WNS25-1.25-Y(Q) |

25 |

1.25 |

194 |

≥96 |

≤80/30 |

57.6 |

9850*3700*4300 |